Sometimes translating process improvement from the text book to the real world can be a challenge. Thankfully, there are examples everywhere if this is how you feel. Let me give you a quick example.

The other day I was at a popular fast food restaurant. What took minutes a few years ago now involves a good deal of queueing. I had waited around fifteen minutes (the lady next to me got served in thirty nine minutes!) when I decided to ask for an update. I looked over the counter and there was food piling up. It was clearly an operation in disarray.

Staff were almost climbing over each other. There was no flow. Nothing was being produced in an obvious sequence. Staff were either in a frenzy or standing looking in disbelief…

Ok, what does this have to do with real world process improvement?

Spotting opportunities

The first step for many of us is simply to spot the opportunities. Seeing what isn’t right, what could be better, is all you have to do.

We don’t need to have a solution on day one. We need to be able to see what isn’t as good as it could be.

Stating the issues in plain English is useful here also. Jumping to a conclusion with your statement narrows your focus, when having all options on the table is useful.

In this particular case we could have said:

“It takes too long for the food to be served to the customers.”

Or, “there is confusion in the kitchen.”

If we had said something along the lines of “the ordering system is too confusing” we might start looking at the system. It might not be the system. It might actually be a training issue, or a work balance issue.

Keep the problem statement factual and basic.

Introducing CCC

A great tool we can use in these situations is CCC, which stands for Concern, Cause and Countermeasure.

Stating the steps another way:

- What is your concern, your problem statement?

- What is behind the concern, the root cause?

- What action do you need to take to deal with the root cause?

That’s it. That’s as difficult as CCC has to be. It is a great tool to use with your teams because it can take the pressure off process improvement. As I said earlier, you don’t need to know the solution on day one. Capture the concerns and leave it there. Let people have some time to think about what is causing the issue (or try some 5 Why problem solving).

When you have had time to do some digging to find out what is causing the issue, then you can define the actions you need to take. Often, if you find the true root cause, you will have an ‘aha!’ moment. Normally a flash of the blinding obvious, but this is about seeing the forest for the trees!

PDCA Complete

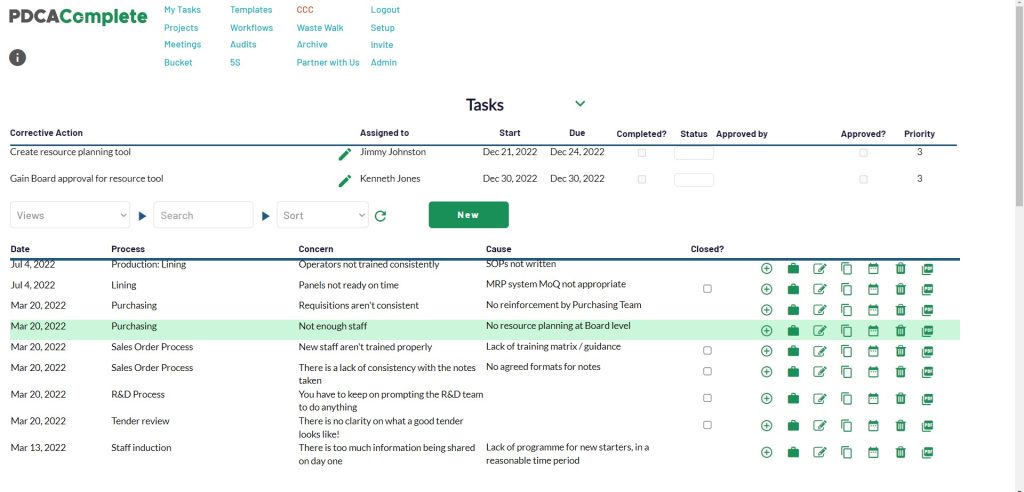

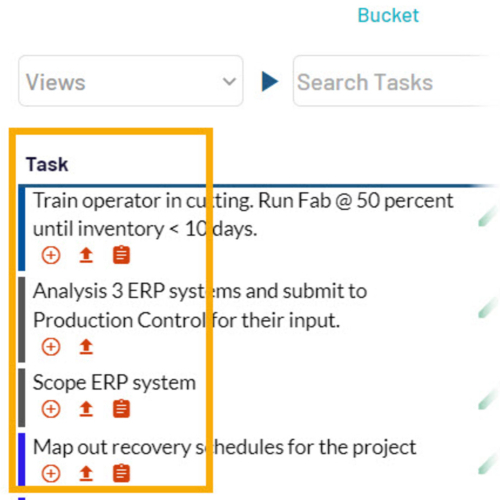

We’ve built CCC into PDCA Complete. This is such a fast and easy to learn tool that we couldn’t leave it out. One of the benefits of using our web tool for process improvement is that you can assign and track actions with the minimum amount of administration.

The actions that come out of your CCC session can be managed by the My Tasks screen, the nerve centre of PDCA Complete. My Tasks allows you to view and filter every task that you are involved with in your organization. This could be tasks from projects, meetings, audits or digitized workflows.

You can move from identifying the issue to managing the improvement tasks with just a few clicks.

Free account

If you haven’t already claimed your free PDCA Complete account, you can do so here.

Our free accounts are for up to three users. These can be people within your business, or collaborators elsewhere. All of the main functions of PDCA Complete are available with the free account. There are some good reasons to upgrade, including:

- Expanding your team past three.

- File / document uploads.

- PDF reporting.

- Organization bulk management tools (such as re-assigning tasks).

If you want to learn more about our subscriptions, check out our pricing page here.

Otherwise, you can sign up for your free account here.

Start spotting process improvements today

Don’t overcomplicate this. Identify things that concern you and write them down. Poke about and discover what is really causing the issue. Don’t settle for the first answer you find, mind you! Dig under the skin of the problem until you find what simple issue is at the cause.

If you do this right, the answer will be something that you can control. Examples of this include training, policy setting, clear instructions, fool proofing and the like.

Have fun embracing process improvement and the rewards it can bring both you and your organization.